Maximising Energy Production and Reducing Fatigue

Maximising Energy Production and Reducing Fatigue

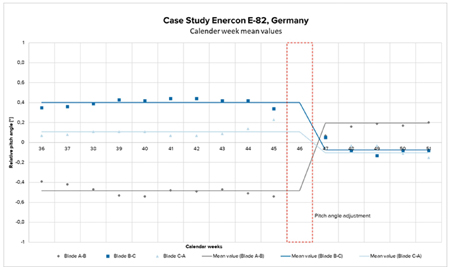

Proper blade alignment in wind turbines is crucial for maximising energy production and reducing fatigue. This article explores a system that addresses pitch misalignment, enhancing turbine efficiency and longevity by ensuring each blade is pitched at the same angle. Pitch misalignment in wind turbines can significantly impact performance. When the blades are not uniformly pitched, it results in decreased aerodynamic efficiency and increased mechanical stress. Various factors can cause blade pitch to become misaligned, such as wear and tear on mechanical components, temperature variations, and human error during maintenance.

By Matthew Stead, Chief Product Officer and Co-Founder, eologix-ping, Australia