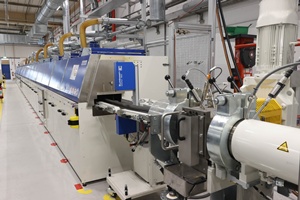

Freudenberg Sealing Technologies has introduced a molten-salt vulcanising extrusion line designed to expand its range of sealing profiles for technical applications, including onshore and offshore wind turbines. The liquid curing method uses a closed-loop salt system heated to around 200°C to provide uniform heat transfer and improved process stability.

Freudenberg Sealing Technologies has introduced a molten-salt vulcanising extrusion line designed to expand its range of sealing profiles for technical applications, including onshore and offshore wind turbines. The liquid curing method uses a closed-loop salt system heated to around 200°C to provide uniform heat transfer and improved process stability.

The 36-metre line enables the production of both small and large cross-section profiles in elastomers such as NBR, EPDM and FKM. The process is aimed at applications that require long-term abrasion resistance, chemical stability and durability, including foundation seals for wind turbines where operating lifetimes can exceed 35 years.

With the new process, the company is targeting sealing applications in wind energy, hydrogen electrolysers and industrial systems exposed to high temperatures or chemicals. The line includes an integrated sensor system for continuous monitoring and tolerances as tight as 0.1 millimetres.